5/10-extra oxalic acid frankfurt abrasive for grinding marble to achieve mirror glossy surface

Product Video

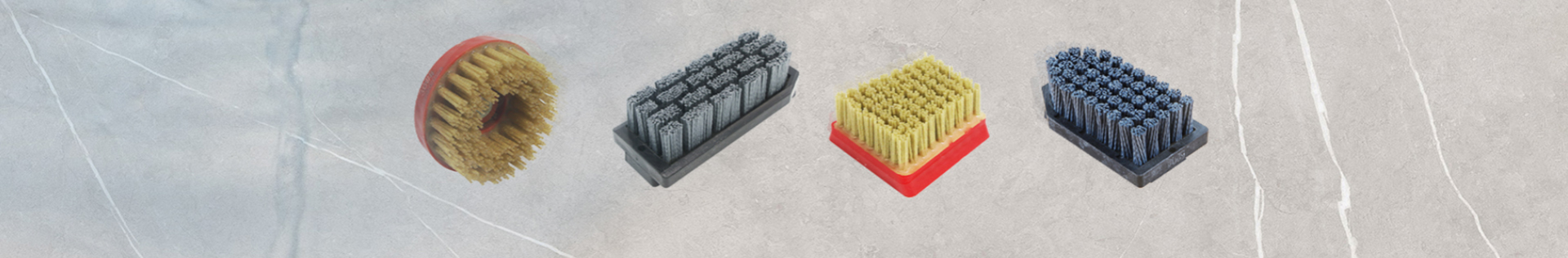

Description:

Frankfurt abrasive 5-extra / 10-extra is made with oxalic acid bond which is used for final polishing step on processing marble, travertine and artificial marble (terrazzo) to get a mirror polished surface.

Working principle: frankfurt abrasive 5extra is made with oxalic acid bond which is having a chemical reaction with marble surface to make it shining after polishing.

5-extra has longer lifespan but less glossy in polishing, 10-extra is more sharper and can achieve higher glossy but lifespan is shorter. Both of them offer different levels of grinding to suit different stones types and finishing requirement.

Product introduction

We recommend using both 5-extra and 10-extra frankfurt abrasive if the machine has enough polishing heads.

Sequence: 1 sets 5-extra + 2 sets 10-extra as final polishing to get a mirror polished marble surface.

Besides, the color and abrasion of marble slabs is the important factors to decide which abrasive you choose. Most of the beige color marbles are easy to polish, no matter 5-extra or 10-extra will do a great polishing effect in most of the situation.

For dark color marbles, you will need all abrasive from calibrating, grinding to

polishing with great sharpness and it is the same for oxalic acid abrasive stone as well, you need to focus more on the polishing quality than lifespan expectation. Therefore, it is better to choose 10-extra abrasive if you process dark color marble.

Application

5-extra and 10-extra Frankfurt abrasive are widely used on marble automatic polishing line or single head renovated polishing machine for marble final polishing in order to get a mirror polished surface.

Parameter

Thickness of abrasive part: 3.5cm

Regular grit: 5-extra or 10-extra

Package: 36 pieces / carton

Feature

Sharp and good property that achieving high glossy within short time.

5-extra / 10-extra frankfurt abrasive are made of high quality materials which are durable to use and enable to withstand the demand of continuous use and also sharpness guaranteed.