Quartz Abrasive

-

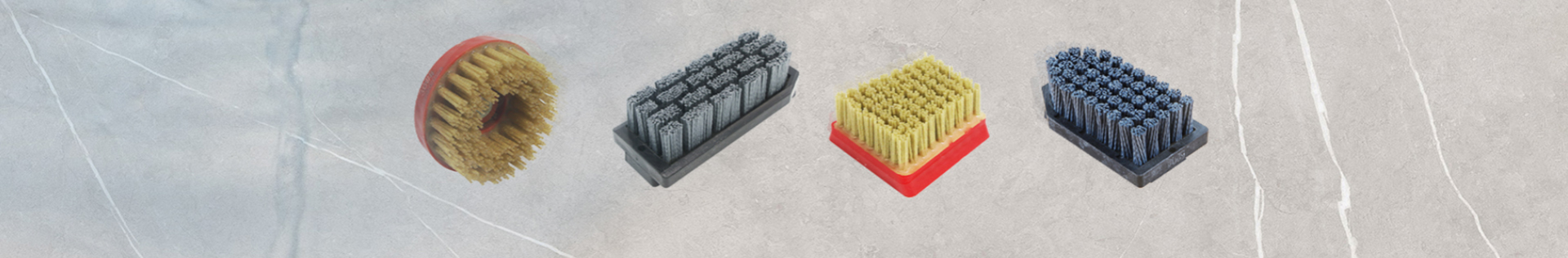

Fickert model airflex antique brush with rubble bristles for matt grinding granite quartz ceramic tiles

Size:L142*H34*W65mm

Airflex antique brushes can soft grinding the surface of granite, quartz, ceramic tiles to create a beautiful texture but not increase too much glossiness, ideal abrasive tools for matt surface requirement (antique finish or leather finish).

Grit: 80# 120# 150# 180# 240# 320# 400# 600# 800# 1000# 2000# 3000#

Applicable machine: continuous automatic polishing machines that for fabricating different kinds of stone like granite, ceramic tile and artificial quartz.

Airflex antique brushes remove the “softer” material in the stone surface to create a beautiful texture while enhancing the natural color.

-

170mm diamond antique brush fickert model 5 steps to create antique finish on granite, quartz slabs

Diamond fickert brushes are usually made of 20% diamond grain and nylon PA612 and other minerals,which is the most sharpest and strongest consumables for grinding granite, quartz, ceramic tiles to achieve antique or leather finish.

The bended edge of plastic mounting is designed based on the polishing head swing principle, it can prevent the plastic mounting breaking the slabs while the wires are almost running out, meanwhile the wires can be used completely, the residue is usually 2-3mm.

Grit: 1# 2# 3# 4# 5#

-

170mm Fickert diamond wires abrasive brushes with sharp and strongest property for grinding artificial cement quartz

Dimension: L168*W72*H60mm

Diamond abrasive brush is the most strongest and aggressive antique brush to deform the stone to desired surface antique and leather finish (matt surface).

Grit: 24# 36# 46# 60# 80# 120# 180# 240# 320# 400# 600# 800#

Fickert diamond brush are usually applied to quartz continuous automatic polishing line, normally 6 pieces as one set installed on polishing head.

-

Granite quartz tools fickert diamond antique brush with nylon wires for processing aged appearance

Dimension: L168*W72*H60mm

Diamond brush is very strong and aggressive to deform the stone to aged appearance.

Grit: 24# 36# 46# 60# 80# 120# 180# 240# 320# 400# 600# 800#

Fickert shape brush are widely used on granite or quartz continuous automatic polishing machine, the whole grinding process is with water.

-

Fickert diamond leather abrasive brush for polishing artificial cement quartz

Diamond leather abrasive brushes are mainly applied on continuous automatic polishing machine for polishing artificial cement quartz, final effect is leather finish.

The diamond wires are composed of 20% diamond grain and nylon PA612,which is the sharpest and efficient abrasive for polishing stone.

The beveled edge design of the plastic brush head is intended to prevent the wires from hitting or scratching the quartz slabs when they are being used at the end of their lifespan.

Sequence: grit 24# 36# 46# 60# 80# 120# 180# 240# 320# 400# 600# 800#

-

Silicon carbide fickert brush abrasive tools for grinding artificial quartz and porcelain tile

Diamond leather abrasive brushes are mainly applied on continuous automatic polishing machine for polishing artificial cement quartz, final effect is leather finish.

The silicon wires are composed of 25-28% black or green silicon carbide grain and nylon PA610,then assemble the wires onto a Fickert brush head using strong glue, so the brush can be applied to specified polishing head on automatic polishing machine.

The plastic brush head is designed with a sloping edge to avoid breaking the stone surface when the brushes are reach to the end of their lifespan, protecting the slabs from scratches and damage.