1.What is antique stone ?

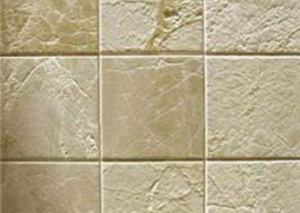

"Antique stone" refers to the special treatment of natural granite or marble, so that the surface of the stone has natural waves or cracks similar to weathering, and at the same time, the natural wear effect of the stone after long-term use (approximate matte or mercerized effect) ). In general, it is to process natural stone into an old-fashioned effect that looks like it has been used for hundreds of years.

2. The advantages of stone antique processing.

Stone antique processing can have uneven satin mercerizing effect, showing the natural crystal luster of stone, and playing a unique decorative effect; at the same time, it can also improve the antifouling and waterproof performance of stone, and can play an anti-slip effect. The antique processing of stone can also avoid light pollution in buildings due to the specular reflection of light. At the same time, the antique stone is easy to repair after wear. At the same time, the chromatic aberration of the color is smaller than that of the polishing process, and it can better reflect the value concept of natural environmental protection.

3.The main abrasive tools for antique processing of natural stone.

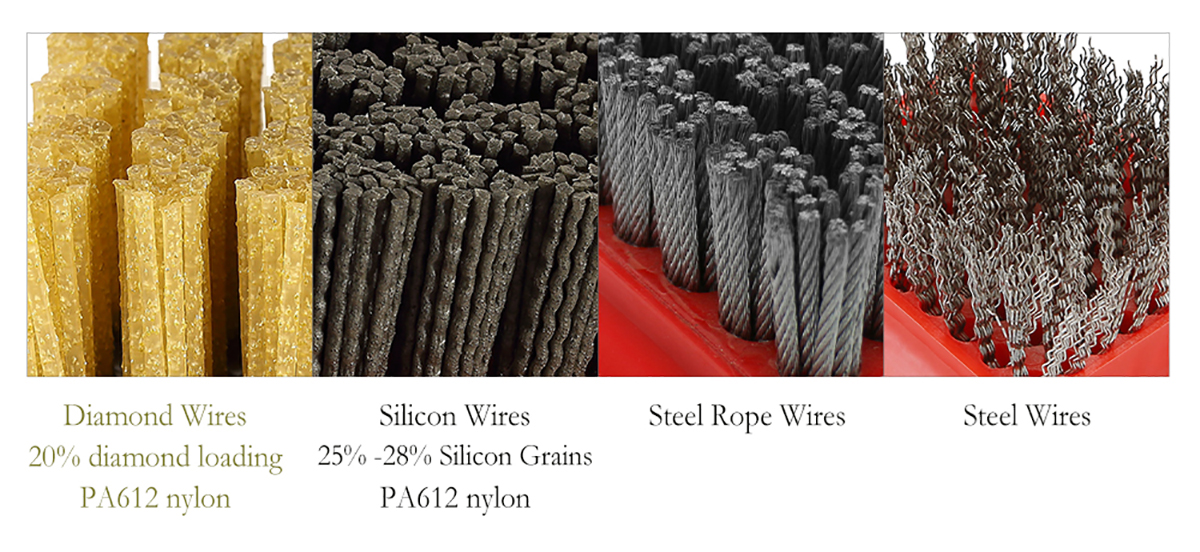

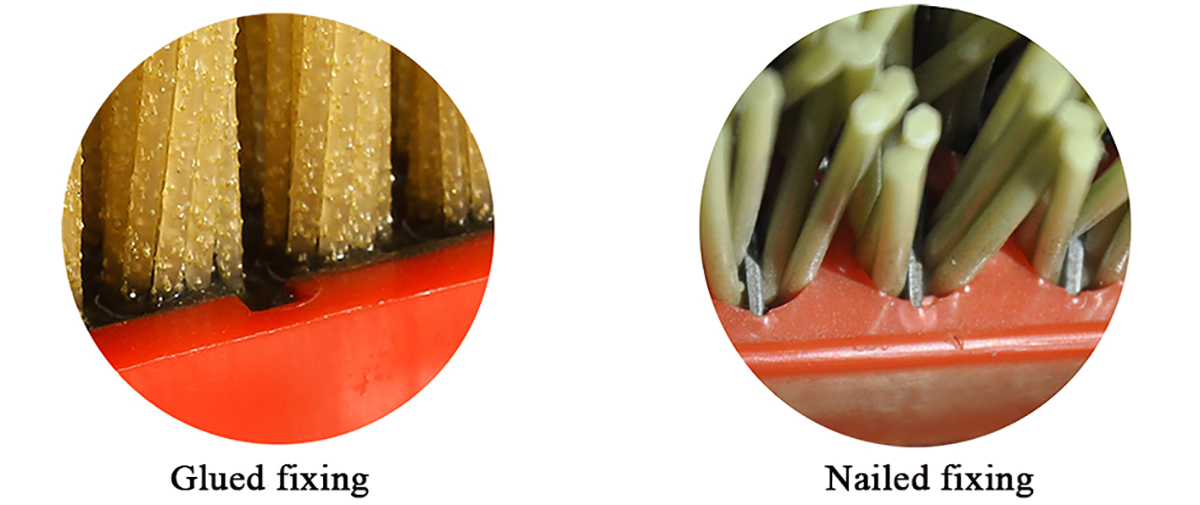

Abrasive brushes are main abrasive tools for antique surface, usually were made of 4 wires materials: diamond, silicon carbide, steel, steel rope.Then installing these wires into plastic or wood plinth, fixing the wires by glue or metal buckle(nailed fixing).

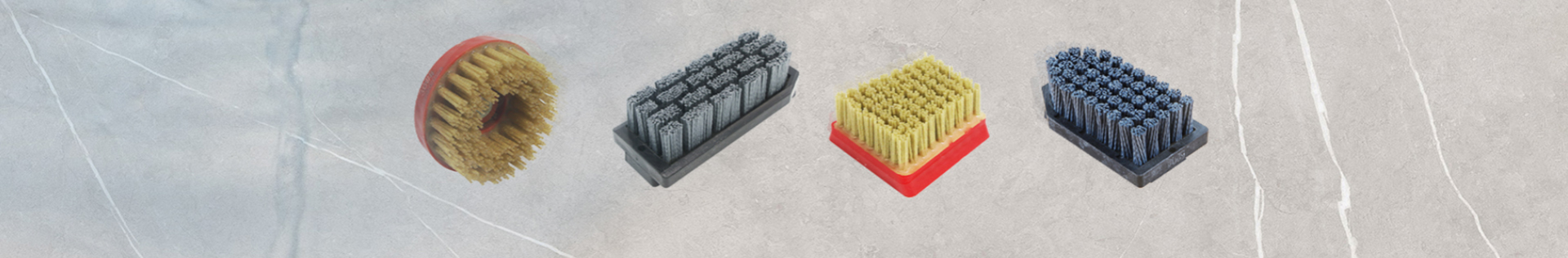

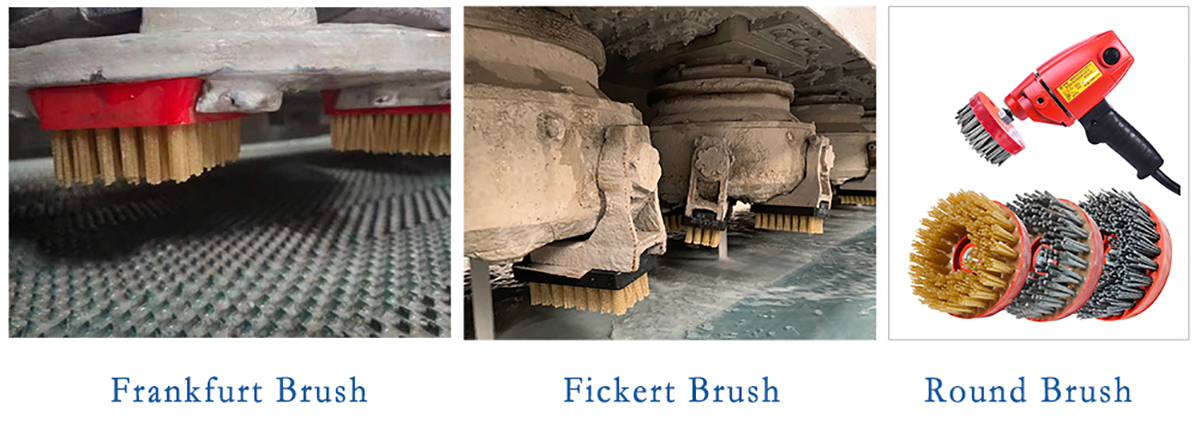

We sorted the abrasive into 3 types according to different shape and applicable machines: frankfurt brush, fickert brush and round brush.

Generally, frankfurt brush is used on hand grinding machines, continual automatic polishing line(for polishing marble, terrazzo), floor renovation machines, etc.

The round brush is used for small manual polishing machines, floor renovation machines;

The Fickert brush is used for automatic continuous grinding machines for polishing granite or ceramic tile or artificial quartz.

4. The processing flow of the antique surface of natural stone(for example granite).

Due to the hard texture of granite, first use fire or high-pressure water to process the granite plate into a rough surface fire plate or rough plate (it can also be processed into lychee sandblasting surface, etc., but the effect is not very good),the rough surface should be rougher than the ordinary singeing board, so as to avoid the stone board being too smooth when using the stone grinding brush in the next step, which will make the layout lose its three-dimensional effect.

Afterwards, according to the specific requirements of the customer, use abrasive brushes from coarse mesh to fine mesh to grind and polish sequentially until the board surface reaches the required effect and gloss. If the customer requires to achieve a smooth and matte effect, it only needs to use diamond brush 36# (or 46#), 60# (or 80#), 120# (or 180#) four processes; if it is to achieve mercerized effect, you also need to add silicon carbide brush 240#, 320#, 400# three processes, of course, if all the processes are done, the effect will be better.

5.The processing flow of the antique surface of natural marble

Because the different materials and texture of different marbles, the processing method should be selected according to the differences in the characteristics of each variety of marble.

Marble with more calcium and magnesium carbonate or cracks and holes can be corroded by soaking in hydrochloric acid for about 10-20 minutes (depending on the specific stone type); after that, use a steel brush to remove residues from cracks and holes to increase the surface of the stone. Finally, use the abrasive brushes from coarse mesh to fine mesh to grind and polish in sequence until the surface of the board reaches the gloss required by the customer.

If it is a marble with more calcite, it can be processed directly with a steel brush. It is also possible to brush the uneven three-dimensional surface effect with a steel wire brush first, and then grind and polish sequentially with a grinding brush from coarse mesh to fine mesh, usually using 36# 60# 80# diamond brush and 180 #, 240#, 320#, 400# silicon brush for processing. If it is a hard marble, the previous steps can be appropriately increased.

Please feel free to contact us if you have any interest, we're delighted to assist you.

Elain: +86-13336414847(Whatsapp / Wechat),email:expert01@huirui-c.com

Alice: +86-13336448141(Whatsapp / Wechat),email:expert02@huirui-c.com

Post time: Apr-24-2023