Stone as one of the most used indoor and outdoor main materials, the surface of stone is very important, not only to bring beauty to the space and to meet the functional needs of the space, if ignored, it may lead to design problems.

Such as: 1.the wet area of the ground stone did not do groove or pickling surface treatment, directly use smooth stone, resulting in the ground is not non-slip; 2. The stone on the shower room floor is not chamfered and polished after pulling the groove, resulting in scraping feet in the shower; 3. The stone on the chopping face of the wall decoration is dirty and not easy to clean.

First, why do stone surface treatment?

- to meet the functional needs, different Spaces, different designs, need different stone properties to meet their functions. For example, in the application of external stone, the treatment methods such as chopping face and litchi face are used to reflect the thick feeling and strength of the stone.

- to meet the aesthetic needs, it is self-evident that any decorative materials in space decoration, different stone surface treatment methods, can also meet different design concepts. If you want to achieve a gorgeous effect, the highlight stone is inevitable. In addition to the natural texture and delicate texture, the rich surface treatment form and plasticity of the stone are the essential differences between it and other materials.

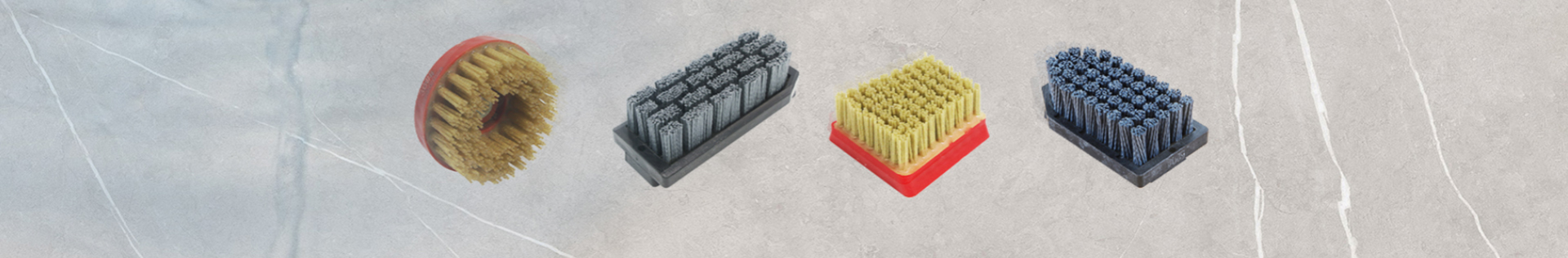

Second, the common surface treatment process of stone.

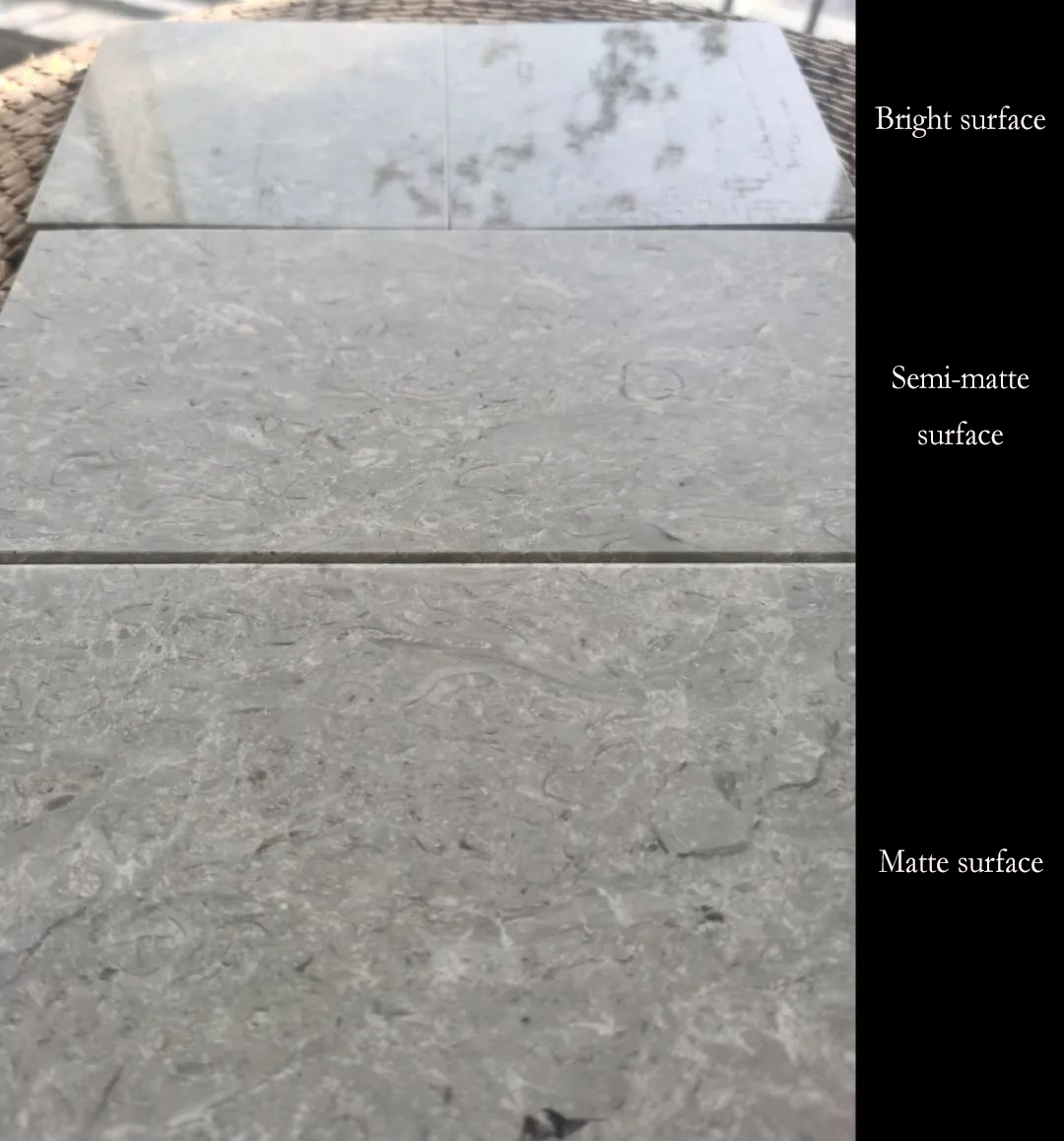

Bright surface(shiny surface): the surface is flat, polished with resin abrasives on the surface, so that it has a mirror-like luster stone luminosity can be 80, 90 degrees, characterized by high luminosity, strong reflection of light, and can fully display the rich gorgeous color and natural texture of the stone itself.

Matte surface: The surface is flat, and the surface is less polished with abrasive brushes. The luminosity is lower than the polished surface, generally about 30-50. Light reflection is weak, the surface is smooth and smooth.

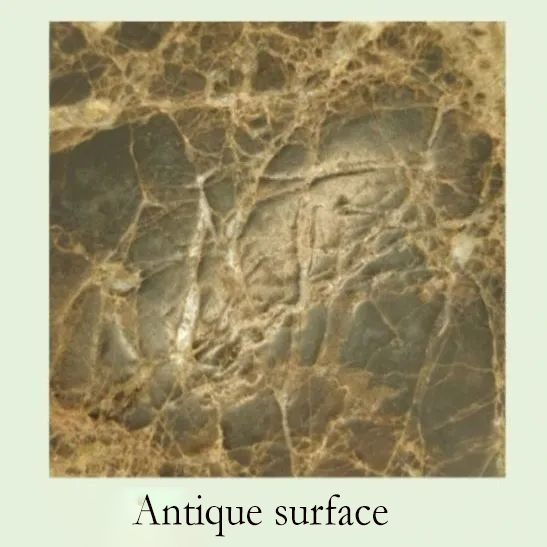

Antique surface: through the steel brush & diamond brush and silicon brush grinding, brush antique water and other ways, so that the stone surface appears bumpy natural effect. Antique surface generally needs to be combined with steel brush, pickling, water flushing, fire and other processes, and then combined with polishing and grinding.

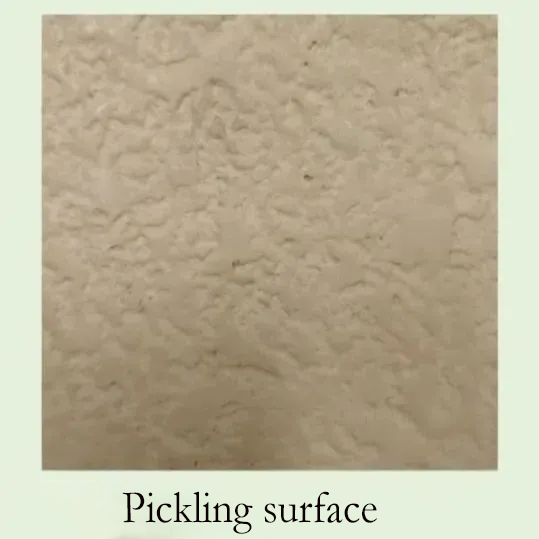

Pickling surface(acid cleaning surface): Use strong acid to etch the stone surface, so that the surface has corrosion marks, uneven, the appearance is more simple than the polished surface, generally used for granite.

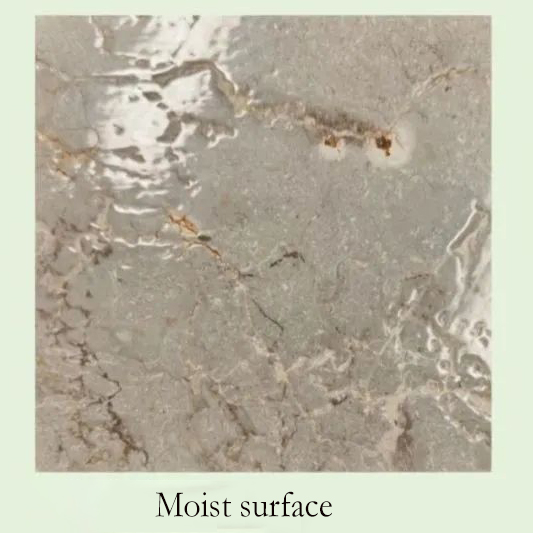

Moist surface: After grinding with steel brush to make antique surface, high-gloss polishing with resin abrasives, so that the stone surface has irregular concave and convex feeling at the same time, with high brightness. Suitable for impurities, rust line more stone.

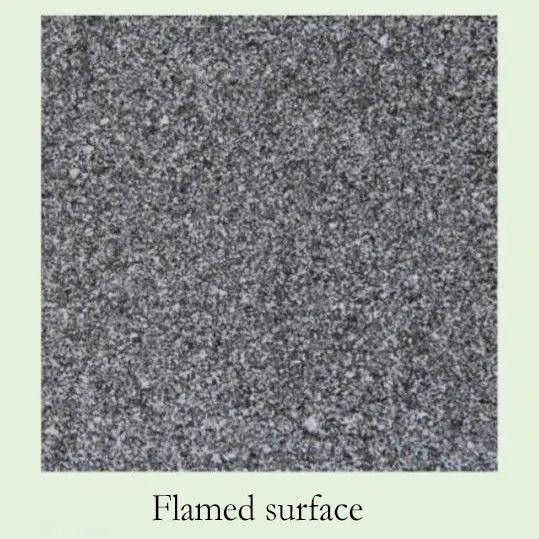

Flamed surface: The use of high temperature flame to process the rough surface of the stone surface. The stone thickness is at least 2CM. The surface of the fire surface is rough and naturally non-reflective, fast processing, generally used for granite processing.

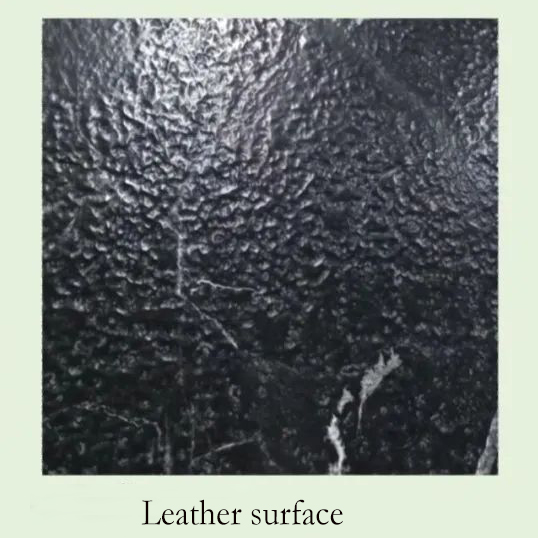

Leather surface: After pickling to make antique surface, polished with abrasive brush, so that the stone surface has a regular concave and convex sense at the same time, the leather texture of high brightness. Suitable for stone with good density and less impurities.

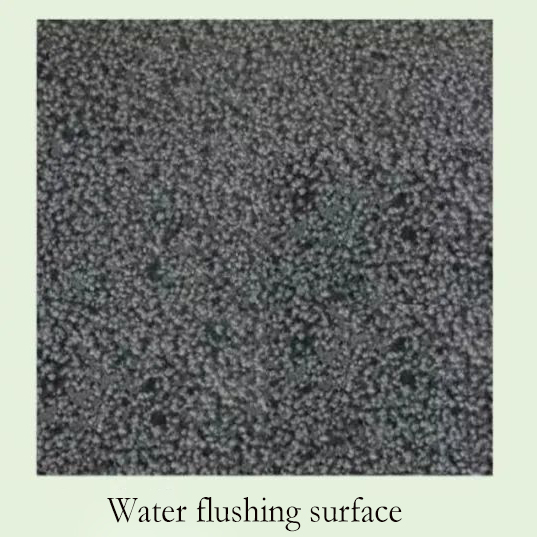

Water flushing surface(water-jet surface): Use high pressure water to directly impact the stone surface to peel the soft texture of the component, forming a unique decorative effect of rough surface. Generally used for granite processing.

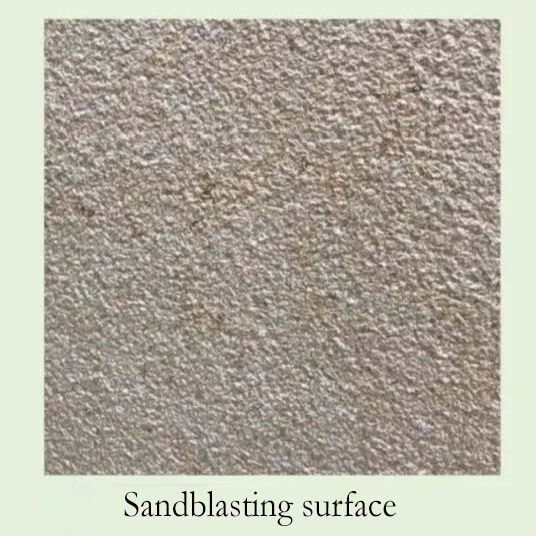

Sandblasting surface: Use ordinary river sand or carborundum instead of high pressure water to wash the surface of the stone, forming a flat frosted effect decorative surface, generally used for granite processing.

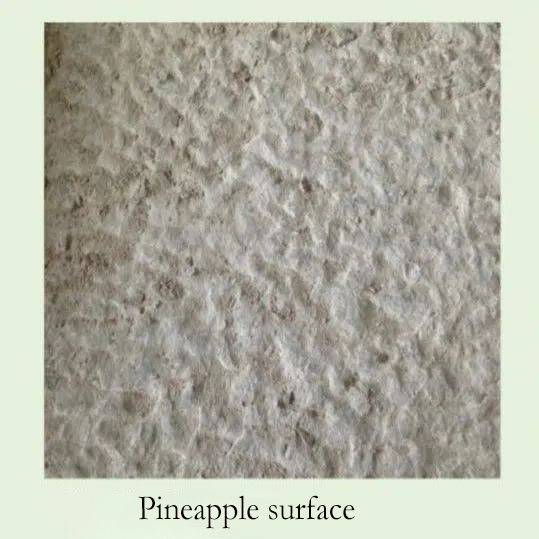

Pineapple face: A plate shaped like pineapple skin struck with chisel and hammer on the stone surface, generally used for granite processing.

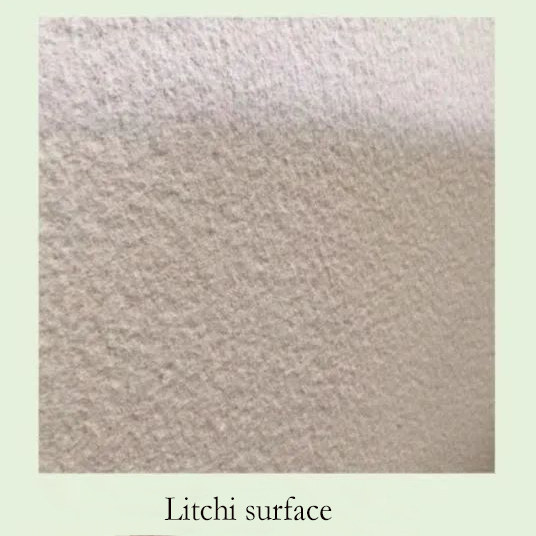

Litchi surface: with a diamond bush hammer shaped like litchi peel on the stone surface to form a rough surface shaped like litchi peel on the stone surface, generally used for granite processing.

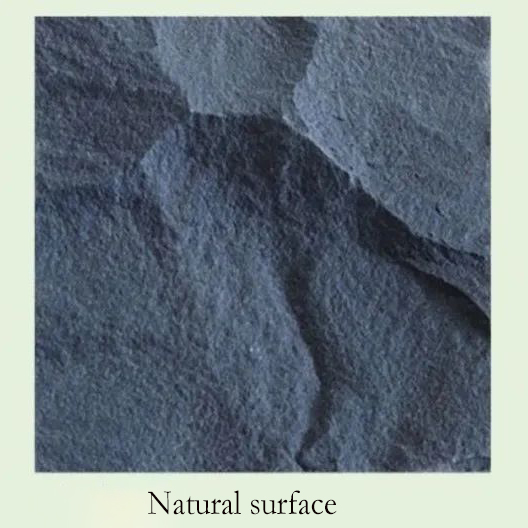

Natural surface: refers to the processing method of splitting a stone from the middle with a hammer to form a large uneven surface like nature, generally used for granite processing.

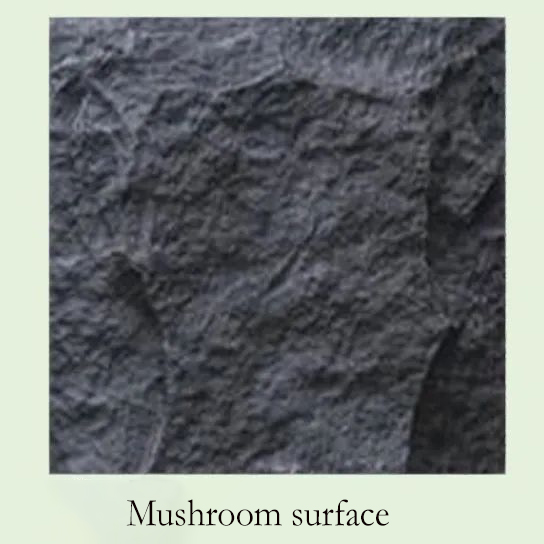

Mushroom surface: The surface of the stone is struck with a chisel and hammer to form an undulating hill-shaped sheet. Thickness requirements: The bottom is at least 3cm thick, the raised part is generally more than 2cm, generally used for granite processing.

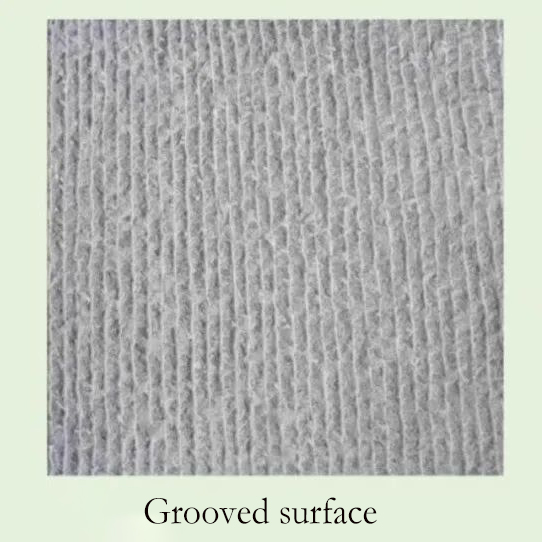

Grooved surface: A unique visual effect presented by a groove of a certain depth and width on the stone surface.

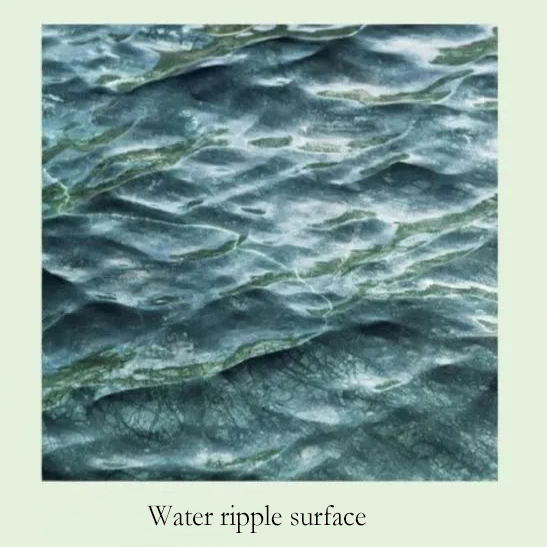

Water ripple: Using sculpting method to make water ripple shape, and then grinding and polishing, showing the rippling water ripple effect.

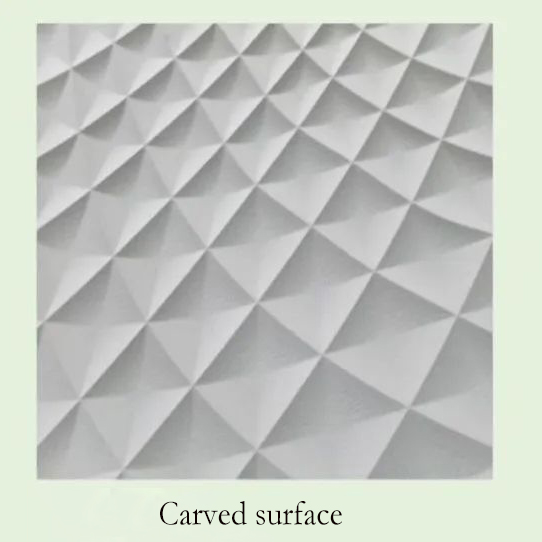

Engraving surface(carved surface): Through engraving, complete a variety of modeling patterns. Often used in lime stone materials.

Post time: Oct-21-2023