In recent years, the international situation is complex and changeable and the overall economic downturn, energy prices rise but the overall purchasing power decline and other factors, with the market competition intensified, the sales pressure of large categories, flow-type products is increasing, and the profit is becoming more and more meager, so more and more enterprises are interested in the difference and profit space brought by antique bricks. That means more competition.

To achieve the leading position of antique products, we must not only pay attention to R & D and innovation, but also walk in the forefront of the industry. To be strong in the field of antique bricks, we also need to be leading in terms of technology, technology, new product development, color and quality, and continue to bring new processes, new products, and lead the fashion trend.

Antique tiles are highly personalized tile categories, and their value plasticity has a lot of space, and prices are big difference because of different quality products. Therefore, which level of products involved in the output of enterprises should have a clear positioning to accurately link their corresponding customers, so that their respective prices can be staggered.

In addition, by improving product differences, establishing brand labels, and creating brand recognition, we can naturally differentiate prices in the face of customers.

Below I will introduce to you the ceramic and various stone antique bricks are made with what tools.

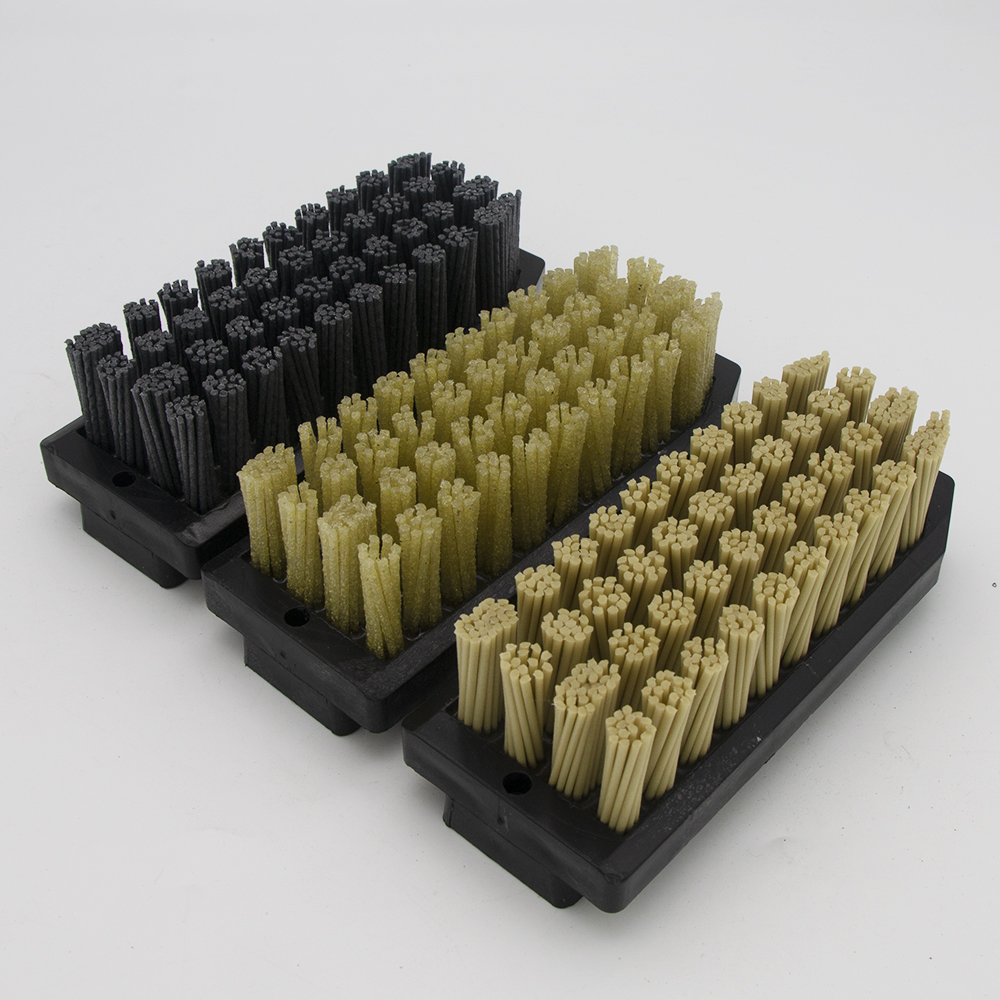

(1) Ceramic tiles

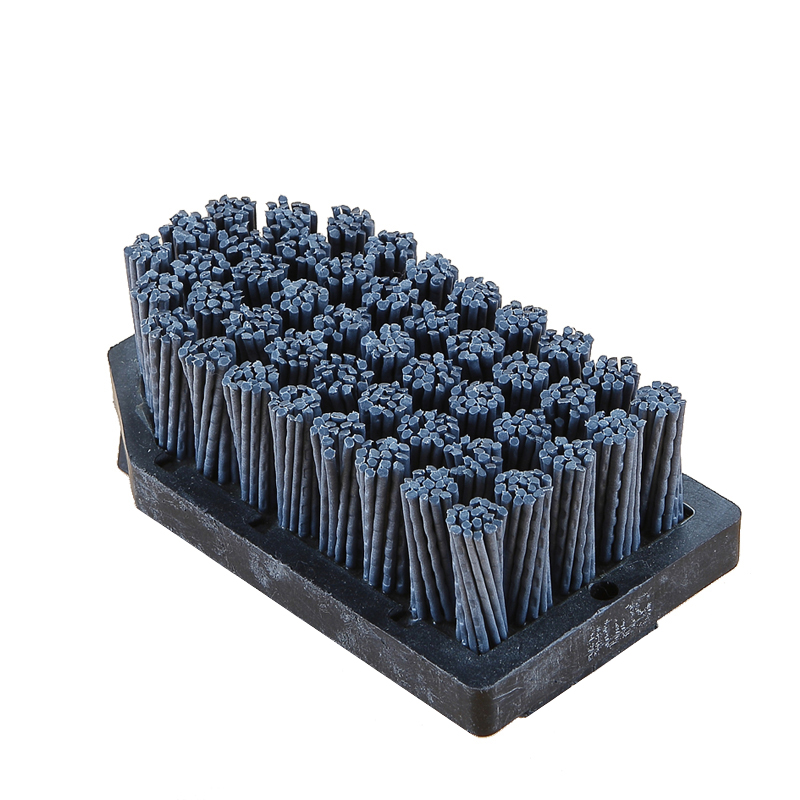

At present, the largest use of ceramics factory is this 170mm fickert type silicon carbide antique brush. The common grits are 180# 240# 320# 400# 600#.

Its brush wire is mainly composed of silicon carbide abrasive and nylon materials, with a certain grinding and glazing function. It follows the grain of the ceramic material, throwing off the soft particles on the ceramic surface, leaving the hard particles to form a bump, which finally formed the concave and convex surface, the gloss reaches between 5-15 degrees, imitating the tone of nature, no reflection under the light, the eyes are very comfortable.

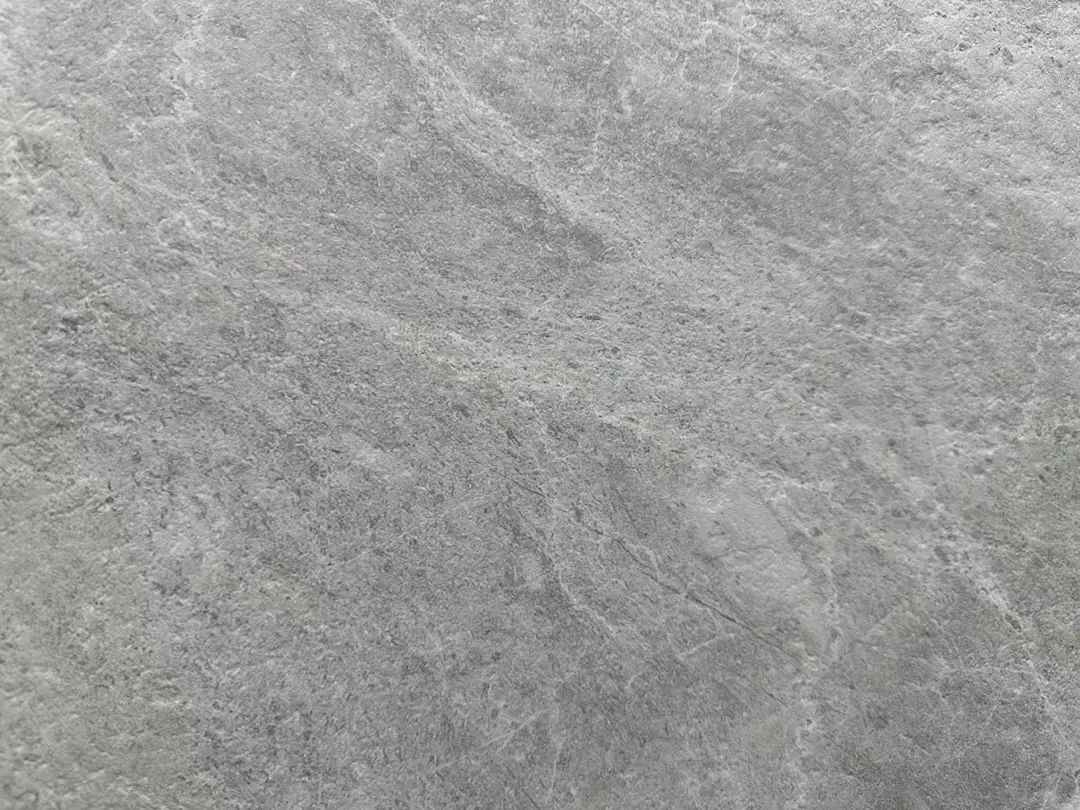

(2) Quartz stone

Quartz stone antique surface and leather surface (matte) are very common. The main processing tool is 170mm diamond grinding brush, commonly used for 24# 36# 46# 60# 80# 120# 180# 240# 320# 400# 600# 800#.

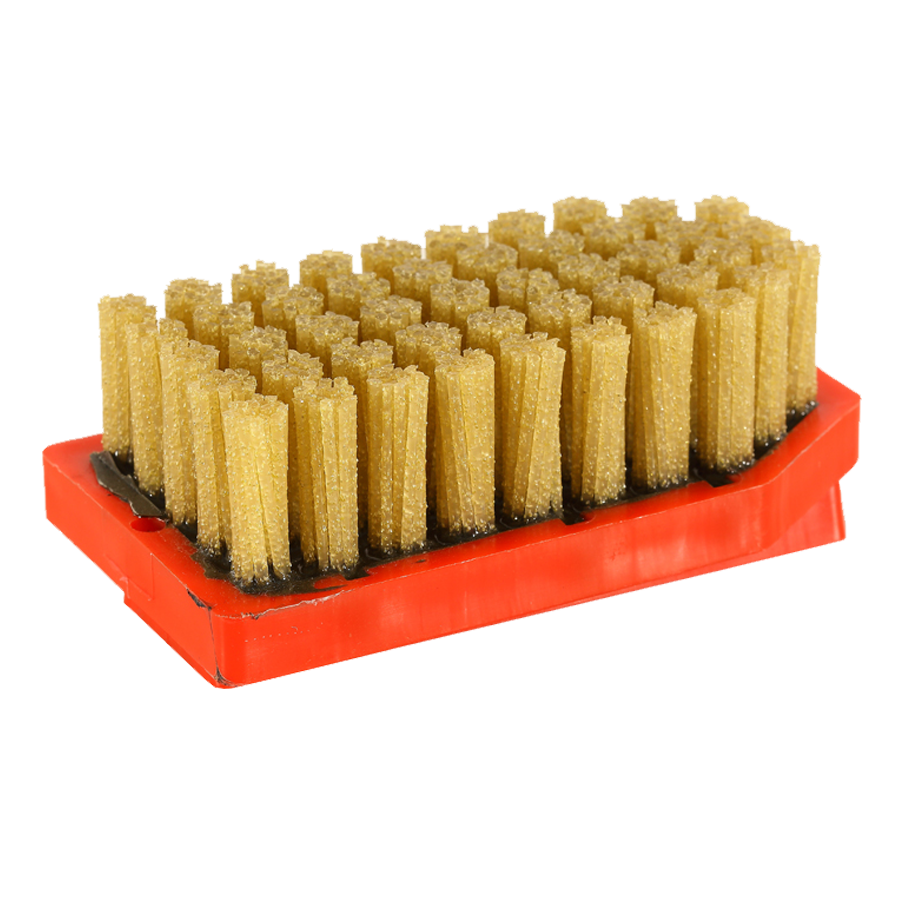

(3) Granite

If it is a floor tile for outdoor, generally it’s flamed surface, if you want to do a delicate antique brick, it must use the following 140mm fickert type diamond brush and silicon carbide brush to grind the perfect antique surface.

(4) Natural marble

The texture of marble is relatively softer than all the above stone, and the grinding head of the polishing machine is generally the use of horseshoe type grinding tools (frankfurt abrasive).

If you want to know more detail about how to process antique surface on different stone slabs, please leave us a message and feel free to contact us by email (langshuobrush@163.com) or Whatsapp (0086-13336448141). Thanks.

Post time: Aug-07-2024