5 steps to make granite surface diamond fickert abrasive brush sharp and durable tools

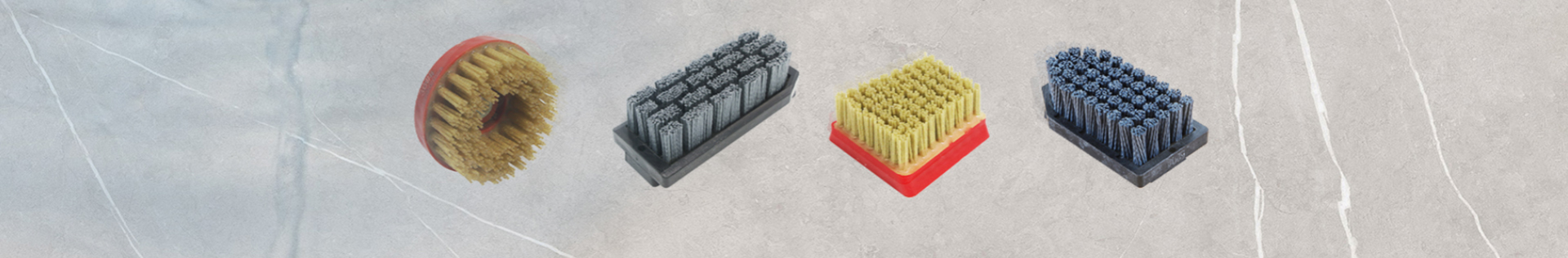

Diamond fickert brush are composed of nylon wires imbedded with 20% diamond content,secured in durable plastic holder. Designed for aggressive surface transformation, these brushes efficiently convert granite surfaces into timeless matte finishes such as antique, leather, or litchi textures. The non-reflective matte characteristics eliminate light pollution while preserving natural aesthetics.

Traditional antique finishing requires over 10 grit grades (24#-1200#). Through extensive testing, we have streamlined the workflow by customizing a simplified 5-step grit progression. While labeled sequentially as 1#-5#, each brush corresponds to a strategically selected diamond grit grade to ensure optimal surface refinement efficiency.

Application

1. Pre-Polishing Step:

Metal Bond Diamond Fickert 24# – 120#: used first to level the granite surface and remove deep scratches from diamond saw wires. This prepares the stone for subsequent texturing and polishing.

2. Diamond Fickert Brushes Application:

Fickert brushes are widely applied to automatic granite polishing machine equipped with multiple heads, the granite slabs passes sequentially through these heads, ensuring efficient progression from coarse to fine stages.

Polishing Stages

1. Coarse Grinding (Texturing):

Grits: 1#, 2#

Purpose: Creates a deep concave-convex texture for the antique finish. Coarser grits (e.g., 24#) aggressively shape the surface, while progressively finer grits (up to 60#) refine the texture.

Technique: put minus pressure to polishing heads, set it to be -1kg or -2kg, the brushes just touch the slab surface is perfect. Belt speed: maximum is 0.8m / minute.

2. Medium Polishing (Smoothing):

Grits: 3#, 4#

Purpose: Removes scratches from coarse grinding and smooths the surface. Each finer grit eliminates micro-scratches left by the prior stage.

Process: Gradual grit progression ensures scratches are not too deep for subsequent stages to address.

3. Fine Polishing (Gloss Enhancement):

Grits: 5#

Purpose: Enhances glossiness and refines the surface to a delicate, soft touch. Higher grits (e.g., 1000#) produce a satin or semi-gloss finish typical of antique styles.