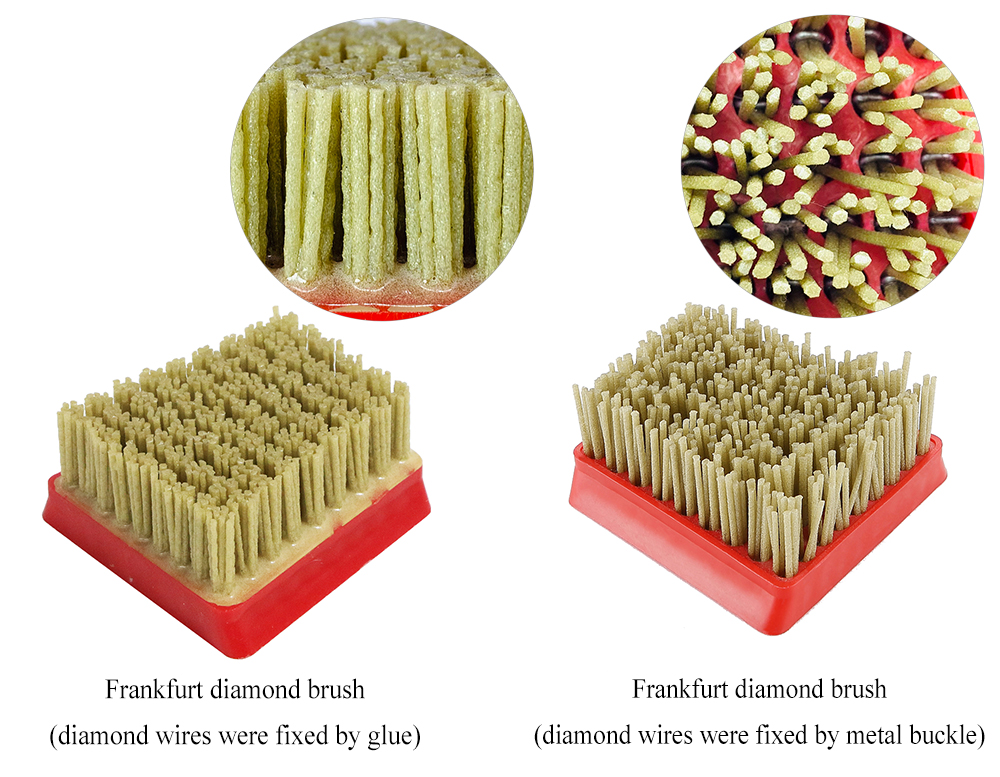

There are 2 methods of installing abrasive filament (like diamond filament and silicon carbide filaments) into the plastic mounting (like frankfurt shape mounting or fickert shape mounting or round shape mounting): one is using glue to fix the wires(many clients called it resin bond type), the other way is installing the wires into the mounting by metal buckle through automatic machines.

You can distinguish them clearly through the below pictures.

So what’s the advantage and shortcoming of these two kind of brushes in different installing way, and which one is better ?

Glue fixing type(resin bond):

Advantage:

1.The installation process is simple and convenient, it usually requires manual installation instead of special installation device (machine).

2.The strong glue can hold the abrasive wires tightly to prevent it falling off and make the brushes more harder which can bear the high pressure while polishing.

3.Each hole on the mounting has been fully packed with wires, so its polishing lifetime is more efficient and has a longer lifespan. Compared with metal buckle installation, it can withstand higher pressure and speed during use.

Shortcoming:

1.The efficiency of manual installation is very low, usually one worker only be able to install 2-3 pieces glued type brushes each hour,the delivery time will be longer.

2.The glue might stick to the workers’ body or clothes while installing, and it has a smell, which requires the workers should equipped with appropriate personal protective equipment.

Metal Buckle Installation:

Advantage:

1.Fast installation speed: It helps liberate the significant amount of human labor,it can be up to 20 times faster than manual installation through the use of automatic machine installation.

2.It has a more scattered wires compare with the glued fixing type brushes, because it has to reserve some space for the machine to reach into the hole while installing. The uneven surface of brushes can polish the concave and convex surface of the stone uniformly.

Shortcoming:

1.Because it has less wires than glued type brushes, and no glue to make it more harder, it can bear less pressure during polishing, its life time is shorter compare to glued type.

2.In general, choosing an installation method depends on the specific requirements of your application. Every way has its advantage and disadvantage, you have to evaluate it and consult our service when you have any question about it.

Post time: Aug-22-2023