1. What is abrasive brushes ?

Abrasive Brushes (Abrasive Brushes) is a special tool for antique processing of natural stone. It is made of stainless steel wire or special nylon brush wire containing diamond or silicon carbide.

It has different thicknesses and specifications for matching Hand grinding machine,continuous automatic grinding and polishing production line, floor renovation machine and manual grinding machine and other equipment.

The stone grinding brush mainly uses the principle of brushing to make the surface of the stone appear natural waves or cracks similar to weathering, and at the same time achieve a satin mercerized and antique effect on the surface, as if it has been used for hundreds of years, and at the same time improve the antifouling of the stone Waterproof performance, and make the treated stone surface have non-slip effect.

2.The working principle of stone grinding brush

The brush filaments used in the stone grinding brush are evenly distributed with silicon carbide sand particles with sharp cutting edges. When the brush is pressed and moved on the stone surface, the brush filaments will bend freely with the uneven surface of the stone. Use the sharp edges of the sand particles to clean the stone surface. Carry out all-round grinding and polishing, with the increase of the number of grinding brushes, the gradual decrease of the volume of sand grains, and the gradual reduction of grinding marks, until the brushed stone shows a satin mercerizing effect while maintaining the uneven surface.

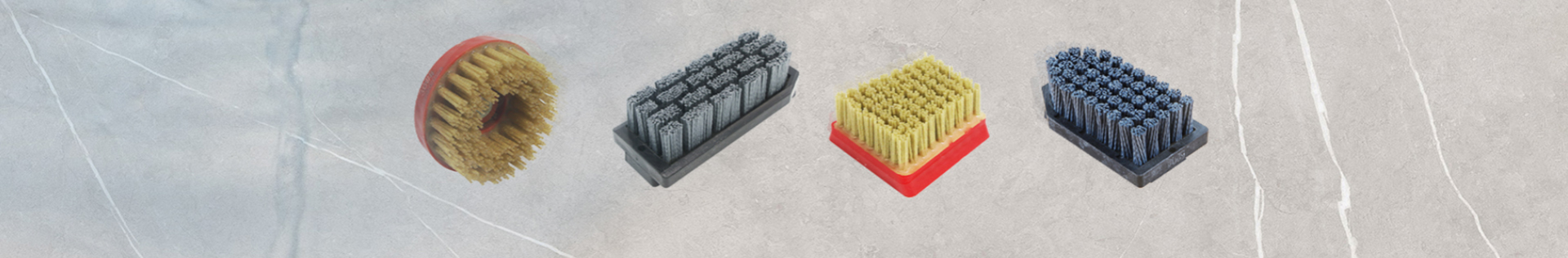

Classified the grinding brushes according to specifications and shapes:

Stone grinding brushes mainly have three shapes: Frankfurt type (horseshoe shape), round shape, and Fickert type. Among them, the Frankfurt type is used for hand grinding machines, grinding and polishing production lines, floor renovation machines, etc. In the industrial production of stone materials; the round type is used for small manual polishing machines, floor renovation machines, etc.; the Fickert type is used for automatic continuous grinding machines.

According to the number of items, there are 24#, 36#, 46#, 60#, 80#, 120#, 180#, 240#, 320#, 400#, 600#, 800#, 1000#, 1200#, 1500# these grit numbers for diamond or silicon wire brushes.

Generally speaking, abrasive brushes and 24# 46# abrasive brushes are used to remove surface looseness and shape the board surface; 46#, 60#, 80# are used for rough grinding; 120#, 180#, 240# can be used for rough throwing; 320 #, 400# are finely polished,600# 800# 1000# 1200# 1500# are premier polishing, so that the stone surface can achieve a mercerized effect. If it is the first time to use abrasive brushes, various models should be tested and selected according to the type of stone and the grinding effect to be achieved.

3.How to choose stone grinding brush ?

A good high-quality stone grinding brush should have the following characteristics:

● The brush wire should not fall off during the working process

● The wire fixing in the brush base should be made of high-strength stainless steel to prevent corrosion.

● The brush wire should be bent in a wavy shape.

● The abrasive sand in the brush wire should not fall off due to the bending of the brush wire.

● Reasonable brush height and density.

● Brush filament should have high hardness and toughness in humid environment.

● Brush wire should have good bending recovery.

● Brush wire should have good abrasion resistance.

4. Points of use for stone abrasive brushes

Stone grinding brush should pay attention to the following points in the production and processing process:

1.Cooling water should be added during grinding and polishing operations. Prevent the brush wire from deforming due to the high temperature generated when the brush wire rubs at high speed.

2.With the working sequence of the abrasive brush model from coarse to fine, the pressure acting on the grinding head on the brush should also be from large to small.

3.Number skipping should be reasonable. Excessive reduction of intermediate links will affect the grinding effect, but may increase production costs.

4. Use a wire brush whenever possible. The use of wire brushes in the first process can reduce the wear of the abrasive brush wires on the rough plate and prolong the service life of the abrasive brushes.

Post time: Apr-24-2023